PET Acoustic Panels

PET acoustic panel products have rapidly gained popularity as a modern alternative to traditional acoustic materials such as mineral wool, fiberglass and foam. Polyester acoustic panels are made from thermally bonded PET fibers, creating a semi-rigid board that is easy to cut, install and maintain in everyday environments. Unlike many conventional products, a PET acoustic panel is pleasant to touch, does not shed irritating fibers and can often be handled without special protective equipment.

One of the main advantages of PET acoustic panel solutions over traditional materials is their combination of acoustic performance and design flexibility. Polyester acoustic panels can be produced in different thicknesses, densities and surface textures to target specific frequency ranges. At the same time, they are available in a wide palette of colors, making it possible to create acoustic wall panels that double as decorative features in offices, schools and hospitality projects.

Traditional Acoustic Materials

Eco-friendly acoustic panel performance is another key factor in the shift from older materials to PET-based products. Many PET acoustic panel lines contain a high percentage of recycled polyester derived from plastic bottles, helping to reduce waste and support circular economy initiatives. Furthermore, polyester acoustic panels are generally low in VOC emissions and can be recycled again at the end of their life cycle, whereas some traditional products are more difficult to recycle or dispose of responsibly.

When it comes to installation, PET acoustic panel boards are easier to handle than heavy mineral boards or friable fiberglass panels. They can be cut with simple tools and shaped on site to fit around architectural details, which speeds up installation of acoustic wall panels and small soundproof wall panel systems. In retrofit projects, the light weight of polyester acoustic panels reduces the load on existing structures and simplifies logistics in occupied buildings.

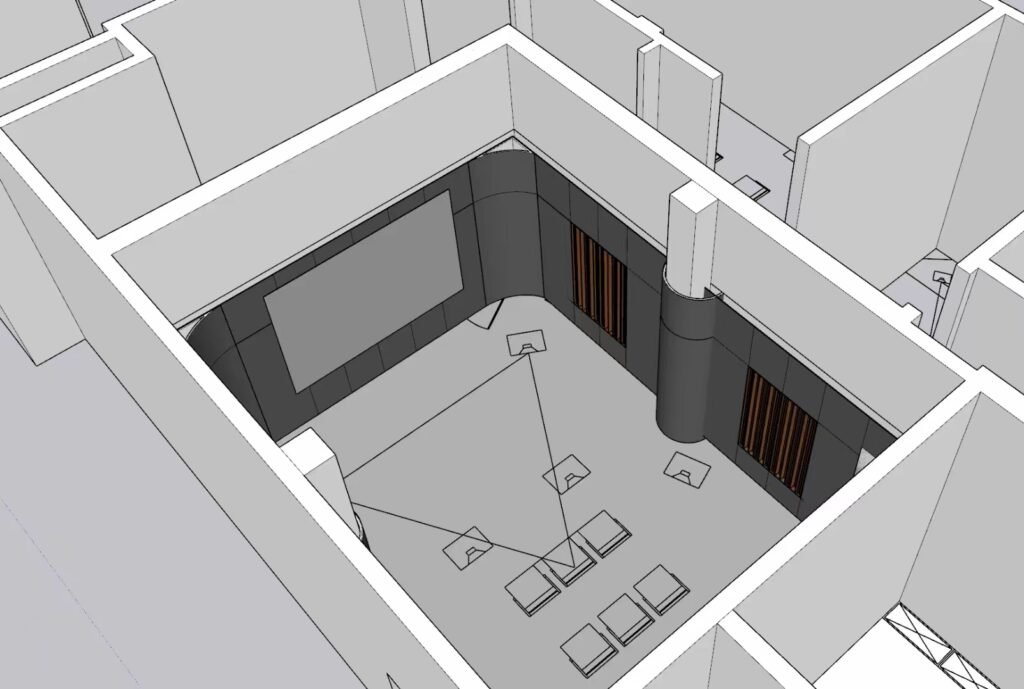

In terms of performance, well-designed PET acoustic panel systems can match or exceed the absorption of many conventional materials at mid and high frequencies. They are particularly effective when used as continuous wall cladding, baffles or clouds, where their surface area and exposure to sound are maximized. For applications that require more extensive sound insulation, polyester acoustic panels are often combined with dense backer boards and airtight construction to form a complete soundproof wall panel assembly.

From a cost perspective, PET acoustic panel products are competitive when the full life-cycle is considered. While the initial material price may be similar to or slightly higher than some basic alternatives, the durability, low maintenance and aesthetic value of polyester acoustic panels often deliver better long-term value. For many architects, contractors and end users, the balance of performance, sustainability and appearance makes PET acoustic panel technology the preferred choice over more traditional acoustic materials.

跳到内容

跳到内容